The post Ultimate Issue: Mini EFIS Units Keep Budget, Complexity in Check appeared first on FLYING Magazine.

]]>While these big projects could make sense for some, we suspect the majority of buyers look for ways to keep the budget and complexity in check.

Enter small-screen EFIS, otherwise known as a budget glass upgrade. These are generally two solid-state gyro instruments—an electronic attitude display and electronic HSI. While you’ll sacrifice screen real estate, you’ll also save big on install labor because mini EFIS units can fit the existing 3-inch instrument cutouts without having to cut new metal, and in some cases, even retaining the old-school plastic overlay.

Here’s a primer on the budget EFIS market, where Garmin and uAvionix are two standouts, with some words on the realities of a bare-bones avionics upgrade.

The $15K Upgrade

While that isn’t chump change, the $15,000 price point is a realistic budget to set, though you might have some left over. And it’s possible to come out of the upgrade closer to the $10,000 price point, depending on the equipment and options.

Still, after adding up the equipment costs and typical labor, there are always extras that add to the bottom line once the airplane hits the hangar floor.

Truth is, while the aircraft may go into the shop for a couple of electronic flight displays, you might decide to also install a new GPS navigator—or maybe a new audio system. The list of add-ons is long, especially for aircraft that haven’t seen an avionics upgrade since the Clinton years. And those extras add up quickly.

The good news is that a basic budget-priced EFIS upgrade is a fine opportunity to clean up old wiring and address problems in the supporting systems. This includes working on the pitot/static system (aging systems often have leakage, which needs to be fixed before installing the new instruments), replacing old circuit breakers, and perhaps fixing faulty panel lighting. If the aircraft has been sitting for a while (or sourced outside of the U.S.), it might not even have mandate-compliant ADS-B.

Bottom line: Before upgrading, our advice is to address the basic systems first, including the transponder, altitude reporting system, and audio systems.

And speaking of cleanup, even the most basic electronic flight instruments provide the green light for removing the vacuum system. When the system hits the rubbish bin, you’ll enjoy a generous weight saving, while also making room behind the panel for future supportability. Vacuum lines, fittings and filters take up lots of space, making it tough for techs to get their hands in it to work.

Once the fundamentals are covered, it’s time for some glass. We’ll start with Garmin’s budget-based offerings.

Small-Screen Garmin

A staple in Garmin’s lineup is the 3.5-inch QVGA color LCD display-equipped G5, which started life as an experimental EFIS before Garmin earned STC for retrofitting them in certified aircraft through an AML-STC covering nearly 600 aircraft models. The G5 is a no-frills instrument but a step up from spinning mechanical iron gyros.

The battery-backup-equipped G5 attitude indicator is $2,725, and the electronic HSI version with GPS nav interface adapter (for connecting to select VHF navs and GPS navigators) is $3,675. Two G5 instruments connected together offer reversionary ADAHRS should one fail, plus there’s a four-hour battery backup if the aircraft electrics quit.

The G5 DG instrument can work for IFR approaches with its electronic HSI but is limited to VHF nav and GPS sources with digital databases, mainly Garmin GNS 430W/530W, GTN 650/750, and Avidyne IFD navigators. The G5 can also work with Garmin’s discontinued SL30 nav/comm and the current Garmin digital nav/comm radios through an RS-232 serial interface.

A couple of G5 instruments have some limitations because to keep in line with the STC requirements, they can’t replace the entire six-pack of flight instruments. Legally, they’ll replace the existing AI or DG, or a single G5 attitude instrument can replace the rate-of-turn instrument. In our estimation, the tech built into the G5 is aging and compared to newer displays it shows—there is no synthetic vision and no touchscreen. Think utilitarian, and while the instruments fit in an existing full-sized instrument cutout, the G5s have square bezels. That means modifying the plastic panel overlays (or false panels, as they’re sometimes called) in aircraft still equipped.

Depending on your particular interface, and which equipment you plan to connect to (including third-party autopilots), you might need Garmin’s $525 GAD 26 digital converter box. There’s also the $412 GMU 11 magnetometer required for heading resolution on the G5 DG. Without it, the instrument will display GPS track and not magnetic heading.

Increasingly, shops tell us that Garmin’s GI 275 beats the older G5 in popularity, given the advanced feature set and overall design. With a form factor that directly replaces most 3 -inch round instruments, the GI 275 is aimed at incremental upgrades and not requiring cutting new metal—plus, you won’t have to modify the plastic overlays, if equipped.

The instruments have a modern 2.69-inch diameter (active screen size) color capacitive touchscreen and an extremely flexible electrical interface potential compatible with a healthy variety of third-party equipment. They can function as a primary flight instrument, EHSI, CDI, an MFD with synthetic vision, traffic and terrain display, and an engine monitor. However, when used as an attitude instrument and heading display, these functions are locked in place per the AML-STC requirements. The GI 275 product line can be confusing because these instruments are available in many configurations—including one that displays Garmin’s EIS engine instrument system.

But for a typical IFR installation, you’ll want the $4,195 GI 275 ADAHRS, which is the one for use as a primary and stand-alone EFIS because it has the sensors for displaying all primary flight data. Again, it’s locked to display only the flight data. Synthetic vision is a $995 option and downloadable, so you don’t have to bring it to a Garmin dealer when adding it later on.

In a budget glass upgrade, it’s common to install a second GI 275 ADAHRS to replace a round-gauge directional gyro, and it connects with the GMU 11 magnetometer for heading resolution. It can be configured as an EHSI, works with a variety of third-party nav sources, and has mapping, traffic, and weather overlay. A GI 275 ADAHRS with the magnetometer is priced around $4,700. Visit www.garmin.com.

uAvionix AV-30-C

The $2,299 AV-30-C (the “C” means it’s for certified aircraft) with a 3-inch color display fits in a traditional 3 1/4 -inch instrument cutout. The AV-30 has been slowly maturing over the past couple of years, and a recent upgrade that makes it compatible for IFR flying has kicked the capability up a few notches. In its basic form factor, an AV-30 is capable of serving as a primary attitude instrument. In a dual installation (one as an attitude indicator and the other as an electronic heading indicator), the AI is required to be locked when used as the primary, although it does display a heading tape at the top of the display.

The AV-30 is loaded with standard features. The short list includes built-in angle of attack, audio alerting, altitude alerting, and primary slip indication. The AV-30-C has an STC with approved model list (AML) that blankets a wide variety of single-engine aircraft with speeds below 200 knots. It’s approved as a stand-alone attitude indicator, as an electronic DG, as a replacement for a slip-skid indicator (it doesn’t have rate of turn—just a skid ball), and it can be used as the required backup attitude display for the majority of primary EFIS systems. It can even be used with the company’s ADS-B/transponder systems.

A dual-unit installation is fair game for removing the aircraft’s vacuum system, but that could need extra approvals or paperwork on the shop level since the specifics of removing the vacuum system are outside the scope of the instrument’s STC. A pair of AV-30s—one as an attitude display, plus electronic pitot static instruments (in certified aircraft you still have to retain the originals), and the other as a heading indicator—is a good way to give an old VFR panel a new lease on life.

At press time, uAvionix released a major upgrade to the AV-30’s capability thanks to external smart adapters. The new uAvionix AV-HSI smart converter accessory adds long-awaited utility to the previously lacking AV-30 IFR interface, with support for essentially all Avidyne IFD and Garmin GTN/GNS GPS navigators. It will work with the GPS-only Garmin GPS 175/GNC 355/GNX 375 navigators, plus the legacy GPS 155XL. This means you can finally display lateral and vertical course guidance for GPS approaches—plus, the converter also works with Garmin’s GNC 255 nav/comm, Garmin nav/comms, and Trig’s TX56/57 nav/comm radios.

For autopilot interfaces, another adapter—the $299 AV-APA—is in the works for communicating with S-TEC rate-based autopilots—which includes the System 20/30/40/50 models. It enables GPS track hold, GPS desired track, GPS bearing, and GPSS digital steering when using the EHSI.

Speaking of add-on interfaces, for aircraft where panel space is limited, the $299 AV-Link can be used to stream ADS-B traffic data to the AV-30 for displaying standard ADS-B traffic symbology. Any portable ADS-B In receiver that works via the industry standard GDL90 Wi-Fi protocol can interface with the display just as it’s done with an iPad. The AV-Link, which piggybacks between the main wiring harness and the AV-30 itself, is only available in experimental installations, for now. Visit www.uavionx.com.

Aspen’s Budget Evoution

The $5,995 Aspen Avionics E5 scales back the features and capabilities built into the flagship 1000 Pro MAX but shares the same drop-in, form-fit chassis that fits the existing holes of mechanical attitude and heading indicators. With a 400×760-pixel TFT Active Matrix LCD screen, the E5 is perhaps the largest of the budget EFIS models with its 6-inch diagonal Matrix LCD screen, and it has a built-in, one-hour backup battery. The E5 shows primary attitude information with altitude, airspeed, and vertical speed, plus an EHSI into a single display with a backup battery.

For IFR capability, the E5 needs to be connected to an IFR panel-mounted navigator but doesn’t require a backup attitude indicator like the Pro models do. It does, however, require Aspen’s ACU (analog converter unit) for connecting with autopilots and VHF nav radios—an accessory that kicks up the price to around $7,000, plus the extra installation effort. You can upgrade the E5 to the Pro MAX version without changing the majority of the hardware. Visit www.aspenavionics.com.

How Much for That?

We think an important step in any budget EFIS upgrade is gathering proposals for larger-screen glass as a comparison. That means bringing the aircraft to the potential installer so they can determine what will and won’t fit.

For sure, the buy-in will be higher, especially when the project requires metal work, but for some—especially with aging eyes—the price delta could be worth it. For others, the smaller screens are a trade-off for an easier installation and lower invoice.

This column first appeared in the Summer 2024 Ultimate Issue print edition.

The post Ultimate Issue: Mini EFIS Units Keep Budget, Complexity in Check appeared first on FLYING Magazine.

]]>The post EDMO: New Antenna Switches Boost Aircraft Comms appeared first on FLYING Magazine.

]]>The Icarus Instruments EXTenna Switch is a small device that, when installed in an aircraft, allows the pilot to use an existing VHF comm antenna with any hand-held VHF radio.

According to EDMO, EXTenna Switch greatly extends the range and readability of most battery powered, hand-held radios that usually rely on the rubber antenna that comes attached to the radio. Often the range on these devices is very limited inside the aircraft.

The EXTenna Switch eliminates the need to install a dedicated backup VHF comm antenna, a process that is often expensive and adds drag to the airframe, as well compromising the aesthetic authenticity of antique and vintage designs.

Installation

Installation can be accomplished by using Minor Alteration FAA guidance, as the EXTenna Switch is a small, nonpowered, passive device that weighs only 2 ounces.

The EXTenna Switch can be panel mounted (P/N EXTSW-1) by drilling three small holes (precision steel drilling template supplied) and applying a supplied label.

It can also be installed in a preexisting 2.25-inch clock hole (P/N EXTSW-2). The unit has two

BNC connectors on the back side. One labeled TX connects to an existing VHF comm radio’s antenna connector (normally Comm 2) using a BNC jumper cable (not supplied). The other, labeled ANT, connects to the VHF comm antenna serving the same radio using the existing cable that was previously connected to the radio.

The default condition has the comm radio directly connected to the existing comm antenna through the EXTenna Switch.

When the pilot needs to use the hand-held radio, a supplied 4-foot cable is attached to its BNC RF jack at one end, and its 3.5 mm connector is plugged into the jack on the EXTenna Switch. This enables the pilot to disconnect the normal comm radio from its antenna and reconnect it to the hand-held radio.

In addition, EXTenna allows effective use of a hand-held radio in emergency situations, such as avionics or electrical failure, or for prestart Clearance Delivery or Ground Control communications.

The unit sells for a suggested price of $129.95.

The post EDMO: New Antenna Switches Boost Aircraft Comms appeared first on FLYING Magazine.

]]>The post Honeywell Demonstrates SURF-A Runway Incursion Avoidance Tech appeared first on FLYING Magazine.

]]>In April, Honeywell announced development of Surface Alert (SURF-A), a software technology that will help pilots avoid these types of events. Now the company is testing the product using its specially equipped Boeing 757.

On Friday FLYING and other media were offered a seat on a demonstration flight. In the left seat a Honeywell pilot took the role of PIC while pilot evaluators from potential customer airlines occupied the right seat and jumpseat on the flight deck.

The idea is that SURF-A will be integrated with Honeywell’s already existing Enhanced Ground Proximity Warning System (EGPWS) and Smart X, the company’s software designed to enhance runway situational awareness that has been aboard many business aircraft for more than 10 years.

Demonstration Flight

The demonstration flight was staged out of King County International Airport/Boeing Field (KBFI) in Seattle destined for Yakima Air Terminal/McAllister Field (KYKM). The flight to Yakima takes about 20 minutes in a 757. The tower operators at KYKM were briefed on the plan and ready.

Also partaking in the test was a Falcon 900, which was designated the intruder aircraft by Honeywell. Its job was to “get in the way” of the 757 on the ground.

The test scenarios were drawn from real-world events—such as the runway incursion at Austin-Bergstrom International Airport (KAUS) in Texas in February 2023 when air traffic control cleared a FedEx 767-300 freighter to land on Runway 18L occupied by a Southwest Airlines 737. The investigation revealed that when the 737 requested takeoff clearance, it was still taxing toward the runway. The controller, presuming the 737 was at the runway threshold, issued the clearance. At the time the 767 was on a less than a mile final. The 737 crew then paused on the runway for 19 seconds to run up the engines per deicing procedures before beginning its takeoff roll.

The crew of the 767 saw the airliner below in time to execute a go around, offsetting to avoid the jet passing beneath them.

The other incursion resulting in a scenario took place in January 2023 at JFK International Airport (KJFK) in New York when an American Airlines Boeing 777 was cleared to taxi to Runway 4L via bravo and kilo, then to cross Runway 31L. It missed the turn, however, and taxied across 4L instead of 31L at the same time a Delta Air Lines B737 was cleared for takeoff on Runway 4L. The 737’s takeoff clearance was canceled, and the aircraft came to a stop approximately 1,000 feet from the other one.

Finally, a wrong-surface event (lining up on a taxiway instead of the runway) and runway excursion, where the pilot gets behind the airplane flying an unstable approach and the aircraft is too fast and improperly configured to land on the first third of the runway.

About the Aircraft

The Honeywell 757 was equipped with cameras in the cockpit and computer monitors in the observer seats (formerly known as first class) to show the pilot’s view. Headsets allowed reporters on the flight to listen to cockpit communications. Mid-cabin on the 757, Honeywell engineers evaluated data during the flight at a series of computer workstations.

The pilot of the 757 contacted Yakima Tower and requested permission to perform each scenario. The tower had been briefed prior to the flight, and each request was approved with the final words “at your own risk” as these are not normal maneuvers for a 757.

How SURF-A Works

According to Thea Feyereisen, a senior technical fellow at Honeywell who specializes in human factors, there is a lot that can go wrong when you mix people and machines, especially when something unexpected happens.

SURF-A uses GPS data, ADS-B equipment, and advanced analytics to pinpoint the exact location of traffic hazards, such as an aircraft ahead crossing the runway.

The software algorithm, combined with GPS position, alerts the pilot of an aircraft equipped with SURF-A as soon as the throttles are advanced. There is an aural alert and auditory warning followed by a textual display on the pilot’s primary flight display.

Company officials said that the technology, once certified by the FAA, can be installed in aircraft already flying as well as in new production aircraft. It was noted that the Honeywell 757 is a 42-year-old airframe and does quite well with the retrofit.

Demos Begin

The weather the day of the demonstration flight was severe clear, so the Falcon was visible on the runway at KYKM during the approach. The 757 was cleared for landing with the usual altitude callouts. When the aircraft was about a mile out, an urgent aural warning sounded, and a female voice urgently announced: “Traffic on runway! Traffic on runway!” The same message appeared in a text message on the pilot’s display. The first warning came about 30 seconds before “landing,” and the second one approximately 15 seconds ahead of touchdown—and a potential collision.

The next two demonstrations involved the 757 lining up to land on a taxiway, and another with the 757 preparing for takeoff with the Falcon crossing well down the 7,604-foot runway ahead—so far down that in the flat morning light of the high desert, the smaller jet could not be easily seen from the cockpit.

In the excursion demonstration, the 757 pilot came in too fast and improperly configured, forgetting to slow down or apply the appropriate flaps. When this happens in the real world, some pilots, although behind the airplane, do their best to make the landing, resulting in an unstable approach where they run out of runway—but not inertia—and go off the end of the pavement. SURF-A supplies callouts of distance remaining, letting the pilot know exactly how much room they have left to work with.

Honeywell estimated that FAA certification of SURF-A is 12 to 18 months away, joining its portfolio of other runway safety products, which include a Runway Awareness and Advisory System (RAAS) and the SmartRunway and SmartLanding software introduced 15 years ago.

The post Honeywell Demonstrates SURF-A Runway Incursion Avoidance Tech appeared first on FLYING Magazine.

]]>The post Strong Geomagnetic Storm Could Impact GPS Navigation, FAA Warns appeared first on FLYING Magazine.

]]>According to the National Oceanic and Atmospheric Association (NOAA), space weather forecasters have observed “at least seven coronal mass ejections [CMEs] from the sun, with impacts expected to arrive on Earth as early as midday Friday, May 10, and persist through Sunday, May 12.”

The prediction prompted a warning for pilots from the FAA.

“Geomagnetic storms can disrupt navigational aids and high frequency radio transmissions used in aviation. The FAA advises airlines and pilots to plan ahead to mitigate possible disruptions,” the agency said in a statement.

NOAA issued a Severe (G4) Geomagnetic Storm Watch and states these watches will be updated through the weekend.

First G4 (Severe) geomagnetic since 2005 has been issued.

— NOAA (@NOAA) May 10, 2024

The aurora tonight (5/10) /tomorrow morning (5/11) may become visible over much of the northern half of the country, & possibly as far south as Alabama to northern California. https://t.co/upPlNYuNev@NWSSWPC @NWS pic.twitter.com/JTHmXtRKOc

According to NOAA, coronal mass ejections (CMEs) are explosions of plasma and magnetic fields from the sun’s corona. These storms can disrupt satellites and infrastructure in near-Earth orbit, “potentially disrupting communications, the electric power grid, navigation, [and] radio and satellite operations.”

The agency refers to the situation as “an unusual and potentially historic event” and warns satellite navigation (GPS) may be degraded or inoperable for hours, and high frequency radio propagation could be sporadic or blacked out.

These storms are also visible from the Earth as displays of aurora and may result in displays being seen as far south as Alabama.

This is a developing story.

WATCH: NOAA’s GOES-16 satellite captured activity at sunspot AR3664 at around 2 p.m. EDT, Thursday

The post Strong Geomagnetic Storm Could Impact GPS Navigation, FAA Warns appeared first on FLYING Magazine.

]]>The post ForeFlight Introduces Reported Turbulence Map appeared first on FLYING Magazine.

]]>“No one enjoys flying through turbulence, whether you’re piloting a single-engine piston or riding in the back of a jet,” said Henrik Hansen, ForeFlight’s chief technology officer.

ForeFlight says the additional feature within the mobile app displays the measured intensity of turbulence at multiple altitudes, making it easy for pilots to find the smoothest altitude along their flight path. ForeFlight Mobile automatically uploads the reports once it establishes an internet connection after the flight or instantly if connectivity is maintained during flight, according to officials.

Turbulence reports are depicted as colored markers on the Maps tab: Gray signifies smooth air, while yellow, orange, and dark orange represent increasing levels of turbulence, ranging from light to severe.

While pilots traditionally rely on weather forecasts and PIREPs for route planning, ForeFlight says its Reported Turbulence method offers distinct advantages, including enhanced accuracy and objective reporting.

ForeFlight estimates its Reported Turbulence layer offers 50 times more turbulence reports than manual PIREPs, per Sporty’s IPAD Pilot News.

Reported Turbulence is available as two add-ons for Pro Plus subscribers. Reported Turbulence (Low) offers access to turbulence reports up to 14,000 feet, whereas Reported Turbulence (All) provides access to reports across all altitudes.

Editor’s Note: This article first appeared on AVweb.

The post ForeFlight Introduces Reported Turbulence Map appeared first on FLYING Magazine.

]]>The post Honeywell Crafts Safer Approaches Through Technology appeared first on FLYING Magazine.

]]>It is not uncommon for air traffic control to pose this question to pilots on IFR flight plans approaching certain airports when the weather is VFR. In daylight, when the visibility is good, the winds calm, and the pilot familiar with the airport—and the approach is a straight in—the visual is no big deal.

But throw in weather, fatigue, low light, pilot unfamiliarity, and a circle to land, and it’s a different event.

Honeywell Aerospace is trying to mitigate these risks, expanding its navigation database to offer flight management system (FMS) guided visual procedures as a stand-alone option.

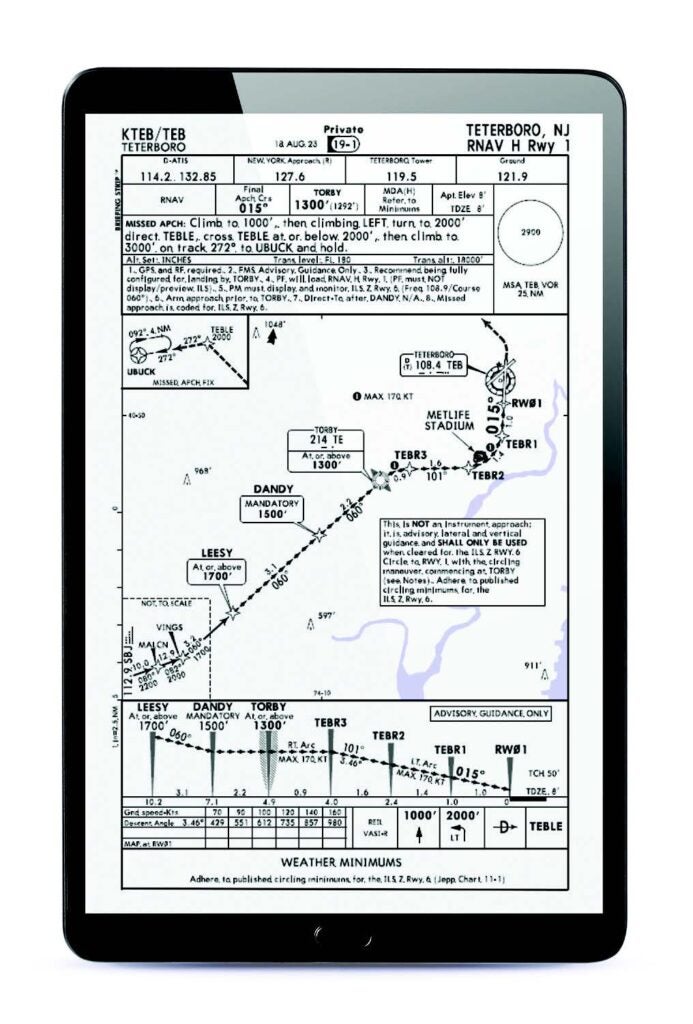

According to Jim Johnson, senior manager of flight technical services at Honeywell, the visual approaches are created in collaboration with Jeppesen. The instructions for the guided visuals look like Jeppesen approach plates but carry the caveat “advisory guidance only” and “visual approach only.” In addition, the symbology on the approaches differs in a handful of ways.

“The FMS-guided visual provides a lateral and vertical path from a fix fairly close to the airport all the way down to the runway,” says Johnson. “You can hand fly them or couple them to the autopilot.”

Visual into KTEB

One of the first guided visual approaches was created for the descent to Runway 1 at Teterboro Airport (KTEB) in New Jersey.

The airport sits in a very industrialized area with the runway blending into warehouses and business parks. Honeywell provides a video of the visual approach on its website that illustrates the value of having that helping hand. Having the extra vertical and lateral guidance from a mathematically created visual procedure allows pilots to better manage their approach, configuring the aircraft in an expedient manner to avoid “coming in high and hot” in an improperly configured aircraft.

This is quite helpful when the aircraft needs to circle to land, says Carey Miller, pilot and senior manager of technical sales at Honeywell.

“Going into Runway 1 at Teterboro on the visual, you are not aligned with the VASI,” Miller says. “There is no vertical guidance, which can lead to a dive to the runway. Add a moonless night or gusty winds, and it can be quite challenging. Not being able to see the airport is a detriment to your energy management. The visual approaches, when coupled to the autopilot, eliminate the guesswork and the overbanking tendency that can lead to stalls.”

Adds Johnson: “The aircraft will fly constant radius turns, [and] you will be on the same ground track every time because the computer knows how to manage the vertical and lateral path. It gets rid of the pilot drifting down or turning early because of the winds.”

Airspace Guidance

The guided visual procedures created thus far have come from suggestions from Honeywell customers, including a visual approach to Chicago Executive/Prospect Heights Airport in Wheeling, Illinois (KPWK). KPWK is in Class D airspace, 8 nm from Chicago O’Hare International Airport (KORD). The Class B airspace for KORD sits above KPWK. There is a V-shaped cutout with various altitudes over KPWK.

The guided visual can help the pilot avoid clipping the Class B airspace during the circle to land—and the dreaded phone call with ATC that results.

The Creative Process

Each approach is created using software tools that take into account the airspace and terrain at the airport, then test flown in simulators to check for flyability.

According to Johnson, the suggestions for where to offer the guided visual approaches come from their customers.

“There are a lot of secondary and regional airports in the U.S. that have both terrain and airspace considerations that make visual approaches very challenging,” says Johnson. “For example, Van Nuys, California [KVNY], has both airspace challenges and a ridge nearby.”

- READ MORE: All Flight Jackets Tell a Story

In some cases, the team may opt to create a visual approach as an overlay to improve safety at airports where closely spaced simultaneous approaches are in use. As this issue was going to press, Honeywell was working on an approach to Runway 28R/L at San Francisco International Airport (KSFO). The visual approach has a briefing sheet with textual guidance, and Honeywell has literally drawn a picture of it.

During development each procedure is flown in a simulator, using a specific briefing sheet that is checked and double-checked for accuracy and usability. Each approach has the ability to be coupled with the autopilot.

Miller cautions it is important to recognize that the visual procedures are not considered instrument approaches in the traditional sense.

“Do not request it as an approach, because ATC will not be aware of it,” Miller says. This information is emphasized on the procedure briefing sheet that accompanies each guided visual approach.

The guided visual approach is loaded in the FMS just like an instrument approach. The pilots can access them with a few pushes of a button, just as they do Jeppesen approaches.

“To use the visual approaches, the customer needs to have a Honeywell-equipped aircraft, and in addition to the FMS database, for an additional $2,000 per year they receive the visual approaches,” says Miller.

To request an approach, contact Honeywell at FTS@honeywell.com. It takes approximately four weeks to put one together.

Coming Full Circle

In many ways, the visual approach procedures represent a modern treatment to the first approaches created by Elrey Jeppesen—yes, that Jeppesen—who became a pilot in 1925 at the age of 18. At the time, there was no such thing as maps purpose-built for aviation. Pilots relied on road maps—which often weren’t terribly accurate, following railroad tracks from town to town or by pilotage and dead reckoning.

In 1925, Jeppesen went to work as a survey pilot and by 1930 was working for Boeing Air Transport, the precursor to United Airlines. This was decades before air traffic control and electronic navigation systems were created. Jeppesen bought a small notebook and filled it with information about the routes he flew. In it there were drawings of runways and airports and information that pilots needed to know, like the elevation of water towers, telephone numbers of farmers who would provide weather reports, and dimensions of the runway and its distance from the nearest city.

In 1934, this evolved into the Jeppesen Company and the notebook into the en route charts and terminal area procedures we know today. Much of Jeppesen’s flying was done in the Pacific Northwest. The Museum of Flight in Seattle is the keeper of the Elrey B. Jeppesen Collection, and for many years there was a replica of his first notebook on display in the Red Barn.

We think Captain Jepp would appreciate how far the approaches he inspired have come.

This column first appeared in the January-February 2024/Issue 945 of FLYING’s print edition.

The post Honeywell Crafts Safer Approaches Through Technology appeared first on FLYING Magazine.

]]>The post Garmin Options Start with Not Ditching Your G430 or G530 appeared first on FLYING Magazine.

]]>No one should be surprised at the situation. Garmin has been whispering about this possibility for a handful of years.

Unfortunately, the verbiage of the advisory was a typical chalk-dry narrative written in legalese, so some folks cut to the wrong chase.

As an operator of the affected equipment, this development is near and dear to my heart. But don’t take my word for it, listen to colleague Larry Anglisano at our sister publication, The Aviation Consumer.

After reengaging with GA as an airplane owner and airline guy a few years back, I was ecstatic that drawing a line with a No. 2 pencil on a sectional chart would no longer be in my future. I could now just follow a magenta line. Wow.

The reason for curtailing support of the GNS 430 and GNS 530 simply became a parts supply issue. It is no longer viable for vendors to produce the parts for 25-year-old technology when the market has a dramatically increased demand for the new technology. Essentially, the old units would have to be redesigned with new innards, so what’s the point?

That said, Garmin hoarded what remained of the supply.

The GNS 430 is most affected because the nuts and bolts module that drives the display are no longer available. The cover glass or lens of the display, however, is still replaceable. The bezel, buttons, knobs, etc. can still be replaced along with the repair of other functionality issues—at least as long as supplies last. So far, the GNS 530 display can be replaced in addition to the items mentioned above. Garmin will also continue to support the data bases.

If your G430 or G530 is repairable, a flat fee starting at $2,000 will be charged. If the unit is not repairable, you’re given the option of having it returned as a doorstop for an assessment fee of $500. Or you can tell Garmin to keep it, and the company will give you a $650 credit toward the new units.

- READ MORE: Garmin GNS 430: Throwaway or Keeper?

The good news is that sending in a unit with an operable display grants you an opportunity to trade it in on Garmin’s new products with a rebate that ranges from $1,000 to $1,750.

Food for thought: eBay lists GNS 430’s from around $3,000 to $7,500, depending upon whether it is WAAS equipped. The GNS 530 lists in the range of $4,500 to $10,000. It’s hard to say exactly the price that these units are actually selling for, or if they’re actually marketable, considering the support circumstances.

Legacy Unit Gamble

Last week while attending the Sun ’n Fun Aerospace Expo, I spoke with Garmin sales manager Jim Laster, who said the company’s concern is the gamble of airplane owners waiting until their legacy unit breaks. Is it repairable or does it become junk?

Although Garmin’s new replacement products can be available to ship the next day, the real concern is how long does that airplane owner have to wait for the avionics shop to schedule an installation? Some shops are six to nine months out.

What are the options? If you simply want to replace the functionality of losing the G530 or the G430, purchasing a GPS 175 Navigator together with a GNC 215 Nav/Com might be the easiest solution. Both units combine on your panel to an area only about three-quarter of an inch taller than a G430, with one a GPS and the other a radio. The combined sticker price is $11,190.

But wait, there’s more. Although the model units mentioned above are new technology with touchscreens and high-resolution displays, forking over $13,795 will buy you a GTN 650xi, which includes features not available on the GTN 175 and GNC 215. The features are too numerous to mention, but suffice it to say, you have to determine if the extra $2,605 is worth it.

The final option is to go all out and buy the GTN 750xi for $19,995. The unit has a larger display screen and is about 3 inches taller than a G530. Decisions. Decisions.

At the end of the day, maybe your current budget is to wait until the G530 or G430 completely breaks. That’s my plan, but it could certainly change. At least Garmin has options. Unfortunately, none of them are cheap.

The post Garmin Options Start with Not Ditching Your G430 or G530 appeared first on FLYING Magazine.

]]>The post Garmin Demos New VHF Radios appeared first on FLYING Magazine.

]]>Sporting a crisp, high-resolution display, they are nicely equipped with a variety of handy features and a smart feature set. It was showing the radio off at Sun ’n Fun Aerospace Expo 2024 in Florida and Kitplanes contributor Larry Anglisano got a product tour from Garmin’s Jim Alpiser.

Editor’s Note: This article first appeared on Kitplanes.

The post Garmin Demos New VHF Radios appeared first on FLYING Magazine.

]]>The post Honeywell Developing Software to Reduce Runway Incursions appeared first on FLYING Magazine.

]]>Runway incursions happen, and Honeywell is focusing on software that will help reduce their numbers.

According to the FAA, a runway incursion is any occurrence at an aerodrome involving the incorrect presence of an aircraft, vehicle or person on the protected area of a surface designated for the landing and take off of aircraft. A surface incident is a closely related event that occurs when there is an unauthorized or unapproved movement within the designated area (excluding runway incursions), or there is an occurrence in that same area associated with the operation of an aircraft that affects or could affect the safety of flight.

Honeywell is working on Surface Alert, or SURF-A, a software technology that will help pilots avoid both.

SURF-A uses GPS data, automatic dependent surveillance-broadcast (ADS-B) equipment, and advanced analytics to pinpoint the exact location of traffic hazards. According to Thea Feyereisen, a flight safety expert, Honeywell’s SURF-A software will be like adding an ever-vigilant “third set of eyes” in the cockpit of an airliner or business jet.

“SURF-A will improve flight crew situational awareness and reduce the risk associated with runway incursions, which are happening more frequently as flight hours increase and airports get busier,” said Feyereisen, who is a senior technical fellow at Honeywell Aerospace Technologies.

At the present time, there are groundside systems that warn air traffic controllers of potential problems. SURF-A will provide a warning to pilots creating a multifaceted approach to runway safety as it gives pilots real-time aural and visual alerts when they’re on a trajectory to collide with an aircraft or ground vehicle within 30 seconds.

According to the FAA, there are four categories of runway incursion, classified as A, B, C, and D. SURF-A targets Categories A and B, which are the most serious as they are narrowly missed collisions or there is a significant potential for collision, which may result in a time critical corrective/evasive response to avoid a collision.

According to Feyereisen, Honeywell has been working on the technology for several years, including tests in Europe and the U.S..

“Things slowed down during COVID-19, but now that flight numbers are back, the margins of safety are more and more narrow,” she said, adding that the company is galvanized when there is a lack of separation or a near miss.

Part of Honeywell’s research includes analyzing FAA data on runway incursions and analyzing the human factors elements. There are a great many ATC operators who are retiring and younger, less-experienced personnel moving into their positions. The same can be said for the cockpits of airliners as the regional and legacy carriers hire relatively low-time pilots to meet their customer demand for travel.

Honeywell, which successfully tested SURF-A capabilities during a series of flights in December has plans to begin demonstration flights in its Boeing 757 this summer for regulators, airlines, and news media representatives in the U.S. and Europe.

“It was gratifying to see how effective SURF-A was in our flight tests at alerting pilots so they could execute avoidance maneuvers,” Feyereisen said. “The system checked all the boxes, and we gathered lots of information that will help us accelerate the development and certification processes over the next two years.

The new technology joins Smart X, Honeywell’s portfolio of runway safety products that also includes Runway Awareness and Advisory System (RAAS) and the SmartRunway and SmartLanding software introduced 15 years ago. Available through a software upgrade to an aircraft’s required enhanced ground proximity warning system (EGPWS), they can boost flight crew situational awareness during taxi, takeoff, and landing.

Honeywell anticipates a “forward fit” opportunity, meaning aircraft will be outfitted with it before they leave the factory.

SURF-A will have the ability to determine where the aircraft is positioned and if there is another aircraft still on the runway.

“Using this knowledge of own ship position, I know if I am taking off and if another aircraft is still on the runway the algorithm in addition to GPS position of the other aircraft will let me know there is an another aircraft on the runway as soon as I advance the throttles,” said Feyereisen.

Part of this is made possible by information obtained from each aircraft’s ADS-B Out data, said Brad Miller, Honeywell chief engineer. In the air, ADS-B gives an auditory and visual warning when traffic is detected nearby.

“This is the extension of that, it implements this runway safety function,” Miller said.

As long as the other vehicle has ADS-B on board, SURF-A will be able to detect it.

The auditory warnings can be in either a male or female voice. Honeywell has professional voice actors who record the required messages “with an appropriate sense of urgency,” according to Miller. The airlines choose which gender they want.

Honeywell expects SURF-A to be released in 18 to 24 months.

The post Honeywell Developing Software to Reduce Runway Incursions appeared first on FLYING Magazine.

]]>The post Going with Glass: The Mother of All Panel Upgrades appeared first on FLYING Magazine.

]]>The Boyds are an aviation family. John Boyd is an A&P and retired Boeing 737 captain from Alaska Airlines. John’s sons, Jason, 32, and Justin, 30, both hold instructor ratings and are planning aviation careers. Jason is also an A&P. The family also owns a Cessna 182 Skylane that it flies regularly. In summer 2017, John Boyd decided it was time to get something a little more comfortable for family travel, and something for the boys to build their multiengine time in.

“I chose the Twin Comanche because I flew one back in the 1980s, and I loved it,” says Boyd. It’s an efficient twin and faster than the 182.”

The ‘Before’

N7163Y rolled out of the factory in 1963. When the Boyds acquired it, the aircraft still had most of the original panel in the original layout—the instruments were scattered, as the classic six-pack arrangement we know did not become the norm for Piper Aircraft until the late 1960s.

The original instrument installation made the airplane difficult to fly sometimes, says Jason Boyd: “I flew an IFR approach at night with that old panel, and my scan was terrible! I vowed never to do it again.”

There were other surprises from the older technology: Activation of the vintage autopilot for the first (and only) time resulted in an “unexpected flight event,” and the Boyds decided “never to turn it on again.”

Shortly after acquiring the aircraft, they began an interior restoration, replacing the brown cloth seats and side panels with cool, gray leather. The interior project spanned several years because John Boyd was still flying the line, and the boys were working full time at a local flight school.

- READ MORE: All Flight Jackets Tell a Story

The panel was not strictly 1960s, says Boyd, as it sported a 1980s-era BendixKing KNS 80 nav unit, which they replaced with a Garmin GNS 530 and flew it like that for a while, getting used to the airplane. If they ever had a question about systems or aircraft quirks, Boyd reached out to Webco Aircraft, the Comanche specialists, located in Newton, Kansas.

“They’ve seen everything,” says Boyd.

Planning for the panel upgrade was meticulous. They went through the aircraft system by system to determine what they wanted to keep and what would be replaced.

Some of the engine instruments or their components were no longer available. They learned that some of the avionics and instrument manufacturers were out of business. Other times, the cost of repair to the often 50-plus-year-old technology made them balk.

There was also the question of instrument reliability.

“The mechanical tachometers were off,” says Jason Boyd. “It made it difficult to sync up the propellers. If you tried to do it with the levers, they would be way off.”

“Finally, the last straw was the erroneous reading on the fuel gauges,” says John Boyd, noting that while no pilot truly trusts their fuel gauges, there is technology available that makes them more reliable, and therefore safer than they used to be, so the pilot has a better idea of how much time they have in the tanks.

Instrument Selection

The decision was made to remove all the analog instruments and replace them with digital. But there is so much out there to choose from, they spent several months shopping and eventually decided to delay, as they waited for Garmin to certify the GFC 500 3-axis autopilot.

“We knew they were working on it, and it was close,” says John Boyd. “I wanted them to certify it before I pulled the trigger. I even offered my airplane as a testbed, but Garmin said no thank you, we already have an airplane.”

Jason Boyd, the family techno-geek, supplied a list of the new instruments, noting his favorite item is the autopilot. “The fact I can pull an engine back in cruise and have the yaw damper hold the airplane straight and level and continue on course is, in my opinion, the ultimate in safety,” he says. “The technology makes this an airplane you can fly single-pilot IFR day or night, as long as you are ahead of the programming.”

The aircraft now sports touch screen panels, top-of-the-line nav/coms, engine monitoring systems, and backup instruments to help a pilot maintain situational awareness even if they are task saturated.

All this glass meant an overhaul of the electrical system was needed, says Boyd.

“When we first got the airplane, it had alternators with old internav voltage regulators,” Jason says. “The old over-voltage regulator was a problem, so we swapped them out for Hartzell Plane Power R1224 regulators. Now the airplane has paralleling alternators.”

Says John: “Everything was chosen for safety. I wanted redundancy and reliability.”

It wasn’t just on the inside. The exterior lighting was also upgraded. One of the first items to be replaced was the 1960s-era tail beacon, which was swapped for a Whelen beacon and Orion navs and strobes that are synced when activated.

“The shell of the rotating beacon is original to keep the aesthetic look of 1963, but the internals are updated to the Whelen/Orion LED Beacon,” says Jason.

Makeover Prep

The combination of a busy avionics shop and global supply chain challenges made for an interesting experience.

“We had to wait our turn at the shop,” says John. “We got on the waiting list at Spencer Aircraft in September of 2022.”

“And it was nearly a year before we got in,” notes Jason, adding that they spent that downtime in their hangar at Pierce County Airport-Thun Field (KPLU) not far away from Spencer preparing the twin for the new digital devices by removing the old mechanical instruments. Doing the removal themselves saved money and, according to John, made for a cleaner installation because they took out all of the unnecessary lines and wiring.

“Sometimes avionics shops simply cut the lines or wires to the old instruments and leave them there to save time,” John explains. “We had the time, so we figured why not?”

Says Jason: “I think we removed about 30 pounds from the aircraft.”

When parts arrived, the PA-30 returned to the shop. When there was a parts delay, the airplane would move back to the Boyds’ hangar. This process continued for several months.

Time to Test Fly

The aircraft was back together by October, and John and Jason took it up for flight tests. There were no surprises, they note. “But it did require a few tweaks,” says Jason.

John points out that they are making adjustments to establish a baseline for operations, such as engine temperatures, so they don’t get erroneous warnings.

“Pretty much the only thing that will keep us on the ground now is icing,” he says.

Flying the aircraft is a different experience now, says Justin Boyd, who shortly after the family purchased the airplane flew it to Iowa with his father and found it labor intensive.

“It’s almost like a different airplane,” Justin says. “The modern Garmin displays and autopilot make it a night-and-day difference from what it was.”

The senior Boyd figures they spent about $80,000 on the panel upgrade, but there is still one more element: the Beth test. Beth Boyd is John’s wife and the boys’ mother. It was because of Beth that John insisted that the aircraft be equipped with Garmin Smart Glide.

With the mere press of a button, the avionics return the wings to level flight, and the aircraft goes into a controlled descent on autopilot. This allows the pilot more time to focus on troubleshooting whatever issue there may be—a big win for safety and peace of mind.

Everything the Boyds Added to Their Panel

• G500 NXi GDU

• 1060 PFD/MFD

• G500 NXi GDU with 700L EIS

• GDL 69A SiriusXM satellite weather, music

• GTN 650 Xi GPS/nav/com 1

• GMA 345 Bluetooth audio panel

• GTX 345 transponder with dedicated ADS-B In and Out

• GNC 255A nav/com 2

• GI 275 backup electronic instrument

• Garmin GFC 500 autopilot

• GMC 507 control head

• GSA 28 Roll

• GSA 28 Pitch

• GSA 28 Pitch Trim

• GSA 28 Yaw

• Falcon angle-of-attack indicator

• DSTR-AOA-9200K with heads-up display

This column first appeared in the December 2023/Issue 944 of FLYING’s print edition.

The post Going with Glass: The Mother of All Panel Upgrades appeared first on FLYING Magazine.

]]>